Infrastructure & Testing

Explore our research and testing facilities & campaigns

Large Climate Test Chamber

Extreme temperature testing for large offshore components

Antwerp

Lead: Sirris

The large climate test chamber and its associated testing services have been designed with several unique features, to facilitate the needs of the wind power industry.

Wind turbines are currently installed globally – sometimes in harsh climatic environments such as cold and icy climates (Scandinavia, China, Russia, Inner Mongolia, China,…) or hot and tropical environments (Middle-east, Australia, South America,, …).

To guarantee optimal performance of wind turbine components, even in the most extreme climatic conditions, the survival capabilities and operating limits of (prototype) machinery need to be tested.

Extreme temperature levels, temperature cycles, humidity, and solar infrared heat loads are simulated in the large climate chamber, one of the largest in Europe.

Mobile Climate Testing Chamber

Full-scale climatic testing for large and high-value systems at your location

Mobile

Lead: Sirris

The challenge

Large-scale and high-value industrial systems are often fixed or difficult to move, making traditional climatic testing complex, risky or impractical. Sirris’ mobile climate chamber brings full-scale extreme environmental testing directly to your site, enabling validation under real operating conditions.

Typical applications are: wind turbine drivetrains and large gearboxes; large electromechanical machines and fixed infrastructure; energy transition systems that cannot be (easily) transported; high-value industrial equipment requiring on-site validation; long test campaigns with minimal disruption to operations.

Realistic testing, earlier insights

By testing systems directly in their operational environment, you gain early insight into performance limits and failure modes.

On-site testing supports long-duration test campaigns and reduces validation risks, improving system reliability, protecting critical assets and accelerating time to market.

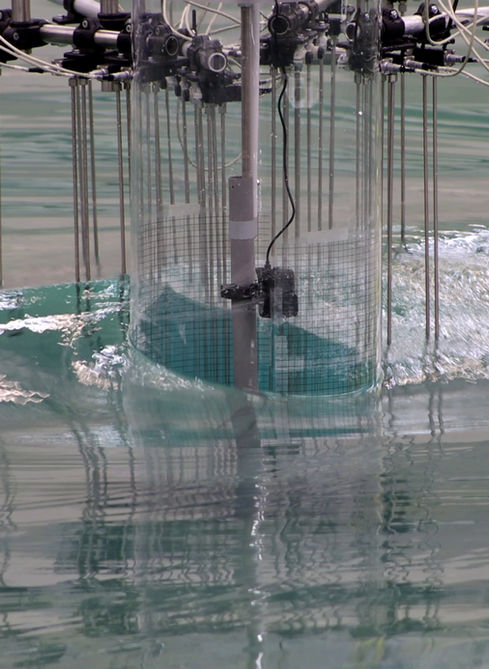

Coastal and Ocean Basin

Wave and current basin for testing offshore structures

Ostend

Lead: UGent

The COB is a state-of-the-art wave-and-current basin designed for scale model testing under realistic coastal to near-offshore conditions. With a 30 × 30 m concrete basin (2.3 m height), variable water depth up to 1.4 m, and a central pit up to ~4.5 m, it allows testing of wave–current interactions from any relative direction, serving floating structures, moorings, coastal defences, marine energy devices, and nature-based solutions. Users benefit from L-shaped wavemakers, bidirectional current generation, active wave absorption, and precise instrumentation including high-resolution motion capture for 6-DOF tracking.

Operated jointly by Ghent University, KU Leuven, and Flanders Hydraulics Research, COB is part of the Flanders Maritime Laboratory and integrated in major research infrastructure networks (e.g. MARINERG-i). It’s fully operational since early 2023, and continually expanding: new capabilities include a modular wind generation system, retractable sand bed for sediment tests, and enhanced data acquisition.

From wave-overtopping studies and offshore structure behaviour to testing of floating PV or wind turbine mooring, its versatile test conditions and rigorous instrumentation provide actionable data for better designs and resilient solutions.

Large Scale Structural Testing

Evaluating strength and fatigue of critical offshore structures

Ghent

Lead: UGent

At OWI-Lab, we offer high-capacity testing of large structural components and assemblies, bringing real-world loads and fatigue into the lab. Our capabilities include full-scale bending, tensile and compression tests, flange and joint evaluation, and fatigue loading under static and dynamic conditions. This allows clients to validate design strength, serviceability, and safety under representative offshore loads.

We combine physical testing with precise instrumentation and advanced diagnostics—strain gauges, non-contact deformation tracking, fracture detection and crack propagation monitoring—to capture how structures behave under load over time. Our rigs are capable of simulating realistic load regimes, including cyclic bending, torsion, and combined load scenarios relevant for offshore wind towers, foundations, and welded connections.

By integrating test-results with numerical modelling and life assessment, we help reduce risks in design, improve material selection, and prolong operational lifetimes. Whether for proof testing, R&D validation, or regulatory qualification, our large-scale structural testing services deliver reliable, actionable data to partners in industry, academia, and offshore infrastructure.

Structural Integrity Monitoring Lab & Rotating Machinery & Performance Monitoring Lab

Evaluating strength and fatigue of critical offshore structures

Brussels

Lead: VUB

The Structural Integrity Monitoring Lab and Rotating Machinery & Performance Monitoring Lab (OWI-lab -VUB) are dedicated to advancing smart technologies that improve the performance, reliability, and sustainability of complex engineering systems.

The core expertise is System Identification (SI), which we continuously refine to develop innovative modelling and monitoring approaches in a digital twin context. By embedding prior knowledge and physical insights into Artificial Intelligence (AI) applications, we create physics-informed methods that enhance accuracy and robustness. This unique combination of data-driven and physics-based techniques allows us to push the boundaries of monitoring, prediction, and control for smart structures and machines.

OWI-lab (VUB) currently operates the largest wind research database in Europe, in terms of turbine coverage, sensor quality, and data longevity. Our mission is to provide windfarm developers and operators with actionable insights into their assets, enabling better decision-making, improved performance, and extended lifetime of critical infrastructure

All features SIM Lab All features RM&PMLab