Cold start-up validation of transformer pumps by the use of a large climate test chamber

The new trend in the installation of wind turbines is the choice of remote areas, where wind conditions are very often optimal leading to new investments for the implementation of wind energy parks. On the other hand, such locations have to deal with extreme inhospitable climatic conditions: extreme cold and/ or hot temperatures, strong winds and gusts, high humidity, ice and/or snow, salty environment (in case of the offshore market). These harsh locations form a huge challenge for the machine itself and maintenance and repairs works in such circumstances can be challenging. In some cases repair works have to be postponed because of bad environmental conditions and thereby noticeably affects the turbine availability and its business case.

For this reason, wind turbines and its components need to be designed and validated to meet the capability of surviving and operating in such extreme conditions. OEM’s and component suppliers are more and more aware of the need to perform advanced validation tests in order to substantiate confidence in its designs, and to increase the reliability and robustness of their products in such inhospitable environments.

EFAFLU is a Portuguese company entirely dedicated to development, manufacture, marketing, technical support as well as after-sales service of pumps, pumping systems and fans. With the increase in the demand of wind turbine installation in harsh environments, EFAFLU recognised the need to validate one of its leading typology of product (oil pumps for transformers) performing cold start-up tests in extreme cold temperatures. For this, EFAFLU teamed up with OWI-Lab.

OWI-Lab is specialised in testing and verification of wind turbine components and full integrated systems as gearboxes, generators, liquid filled and cast resin transformers, power converters, hydraulic systems, etc. in extreme climatic conditions, thanks to its own climatic test chamber – one of the largest of Europe – able to range the temperature from -60°C to +60°C. A specific focus of the climatic test lab is in to test cold-start-up sequences, cold climate / winterisation effects, and icing conditions on large electro-mechanical equipment.

Tailor-made test set-up

According to EN 50216-7 standard – “Power transformer and reactor fittings; Part 7: Electric pumps for transformer oil”, pumps are required to perform a cold start-up test at -25°C. During the test the pump shall reach full running speed following the conditions of minimum voltage with oil at minimum temperature and without overheating or other adverse observations. Besides the standard specifications, the intention of EFAFLU was to extend the standard requirements to a more severe scenario of: -45°C.

The potential risks which lead to failure related to start-up in extreme cold temperatures are:

- Lubricants become viscous and too stiff due to extreme cold, putting exceptional load on the pump;

- Rotating elements in the pump can be at risk because of insufficient lubrication and/or differential thermal expansion of sub components;

- Due to difficulty of the cold start-up, the pump motor can experience overheating problems caused by high current demand;

- Low temperatures effect materials (plastics, metals, rubbers) and cause brittle fracture of materials (sealings, cables, gears,…)

Therefore, the validation in a controlled environment of systems and components to be installed in areas where extreme conditions represent a risk of potential failures is crucial to guarantee the correct operation of the component and to assess the design choices which influence the lifetime.

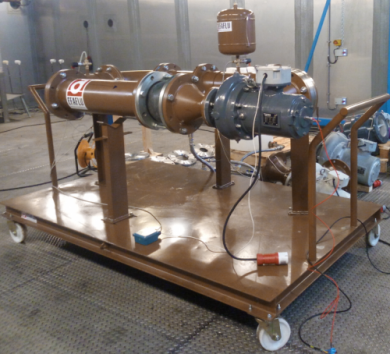

A tailor-made test set-up has been designed and implemented by EFAFLU, able to accommodate different pump models and sensors for measurements at specific locations: a closed loop setup equipped with sensor and temperature sensors, with a changeable orifice plate to adjust the load.

Download this case in PDF format.