OWI-Lab offers industrial R&D services in large scale structural testing and the structural monitoring of (offshore) wind turbine structures for design verification, design optimisation, root cause analysis and stress/load measurements. We also provide the signal processing, advanced data analysis, reporting and consultancy linked to the interpretation of results.

Since 2010 OWI-Lab (lead by the VUB team) developed, installed specific SHM test - and monitoring equipment, scalable automated processing algorithms, and advanced analysis methodologies for the (offshore) wind industry. At this moment several offshore wind turbines in the Belgian North Sea are continuously being monitored in the framework of several national funded research projects coordinated by the OWI-Lab partners.

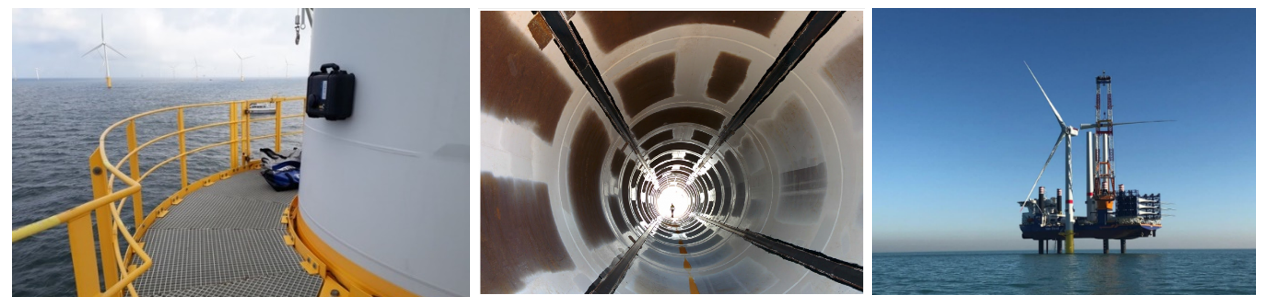

Beside the permanent monitoring solutions OWI-Lab co-developed mobile measurement system for short term (R&D) monitoring campaigns. These mobile measurement systems can be quickly deployed and mainly serve to gain insights in the structural dynamics of different structures with a minimal effort on the side of the owner of the asset. This equipment has already been used in several R&D projects for short term dynamic monitoring campaigns of offshore wind turbines, onshore wind turbine towers, offshore and mobile substations and jack-up vessels. They are also used for noise and vibration assessments of (offshore) wind turbine components such as offshore transformers and gearboxes.

We mainly focus on structural dynamics and strain/load monitoring. To this end we have developed several test and monitoring solutions for both short-term and long-term test -and monitoring campaigns in large funded R&D projects, but also as industrial service to companies. We use a variety of sensor technologies ranging from accelerometers to optical fibers. We therefore work together with several technology & solutions providers (e.g. 24SEA, Com&Sens, PCB, HBM…). The inhouse data analysis tools developed by the OWI-Lab allow us to provide fast reporting and consulting services. Post-processing tools consist of a range of signal processing tools for noise and vibration, operational modal analysis, rainflow counting, load calibration etc….

A project or structural measurement campaign typically consist of defining a measurement plan, preparation and installation of the equipment, data collection, data analysis and reporting. All these steps are done in close cooperation with the industrial partner (s). Our mission is provide good quality data, insights and understanding of your data that allow you to make better decisions. The structural testing and monitoring services are coordinated by the OWI-Lab consortium partners VUB (Prof. Christof Devriendt and his OWI-lab/VUB team which has more than 15 years experience in offshore structural monitoring, signal processing and data analysis) and Sirris (Pieter Jan Jordaens).

Cases story: Structural (damping) monitoring campaigns (Parkwind)

OWI-Lab has been and is performing several structural foundation monitoring campaigns at the offshore wind farm Belwind, which consists of 55 Vestas V90-3MW wind turbines placed on monopile foundations. The wind farm is located in the North Sea on the Bligh Bank, 46 km off the Belgian coast.

More information about continious dynamics monitoring of an offshore wind turbine

More information about damping estimation on an offshore wind turbine